Progressive Metal Stamping

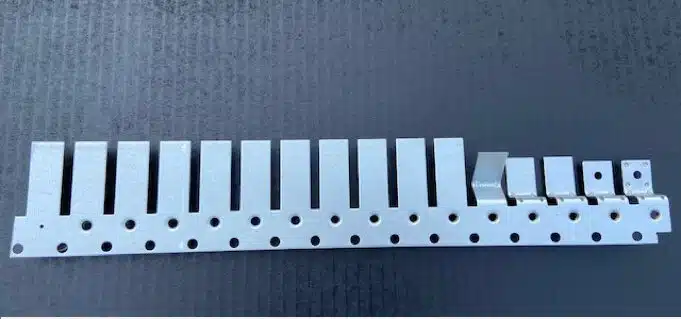

Progressive metal stamping a complex process. With the progressive process, steel advances through different stations of the die. Depending on the complexity of the part, the number of stations is determined and could include punching, blanking, bending, coining, embossing, flanging, etc. At the end of the process, the completed part is produced utilizing just one die.

Common Progressive Metal Stamping Stations

| Coining | Force or pressure used to create a shape by displacing metal |

|---|---|

| Punching | Producing holes in a metal using a punch press |

| Fine Blanking | Accomplishes features often impossible with conventional cutting/punching |

| Bending | Creates angles |

| Deep Draw | Transforms metal into shapes in which depth is greater than diameter |

The Advantages of

Progressive Die Stamping:

Cost effective

• Quicker Set Up

• Speed of Production

• Less Scrap

Streamlined Manufacturing Process

High Quality, Uniform Parts

Dies Long Lasting

Production quantities range from one to millions of pieces with J.I.T and blanket programs.

Require more than just the stamping?

Plating, heat-treating, assembly, packing are just a few of the additional services offered.

Contact Reliable today by clicking the below link or calling 888-331-9590. You’ll be glad you did.

Reliable Metal Stamping Co., Inc.

Experience you can trust. Reliable people you can count on.